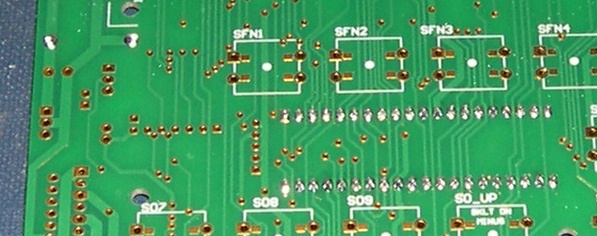

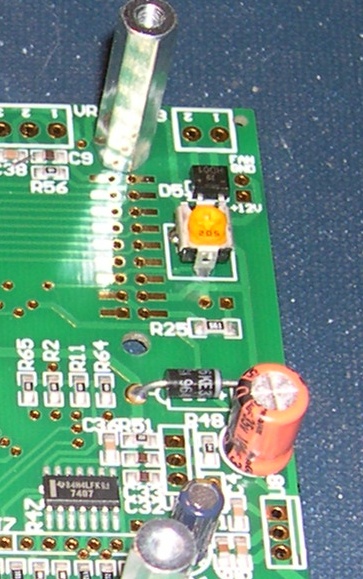

The basic ELS kit consists of all the parts in the photo below:

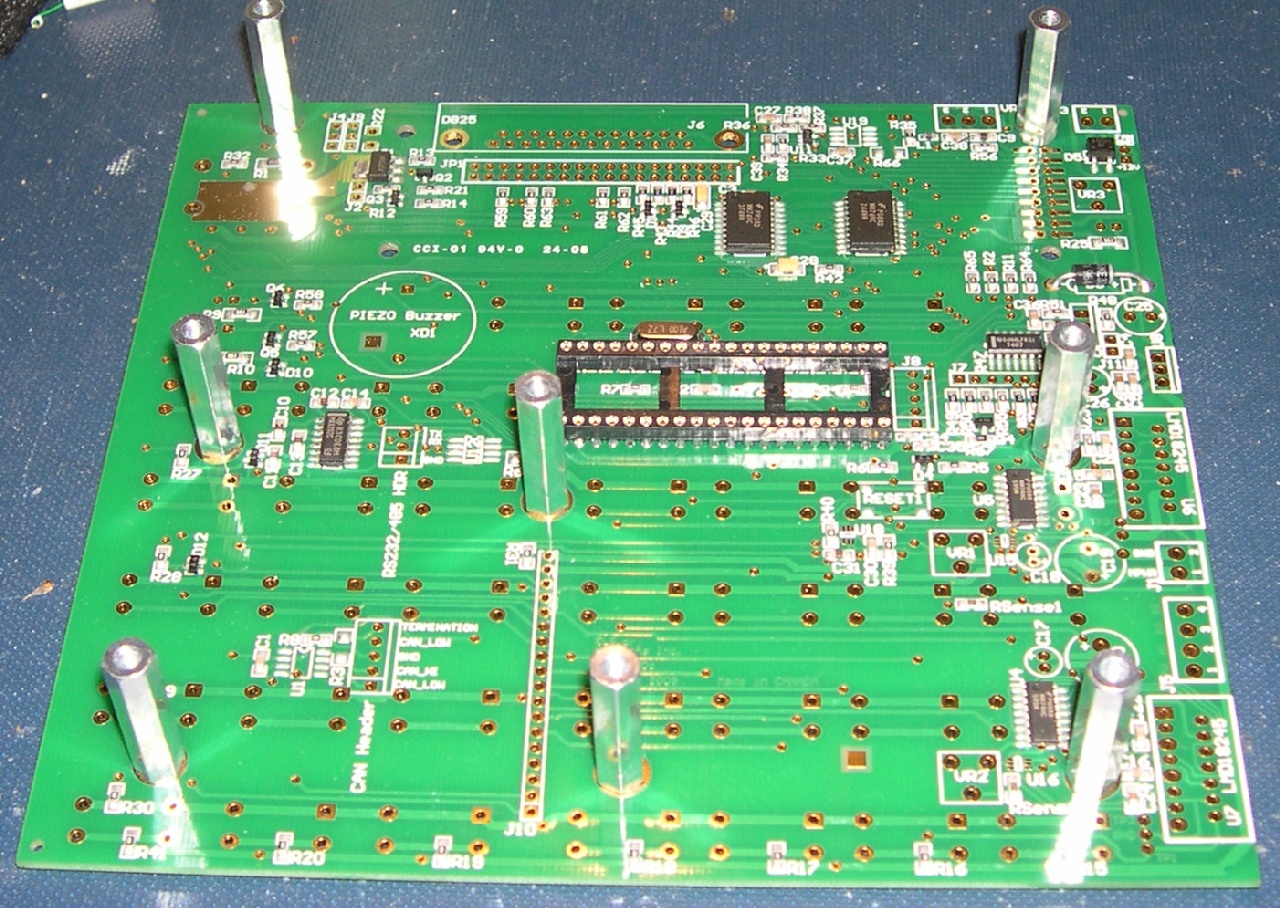

If you bought the optional hardware mounting kit you will also have received what is shown in the photo below: The assembly instructions that follow assume you have this kit but you can build an ELS without them.

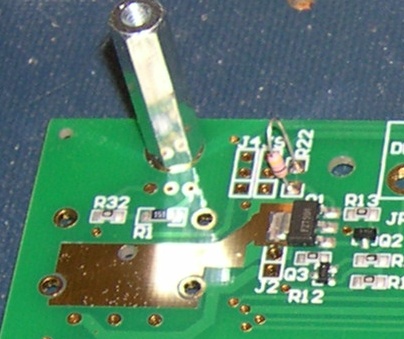

So let's get started. Open the paper envelope and remove the parts. The P6KE33 transorb is installed first on the bottom side of the board.

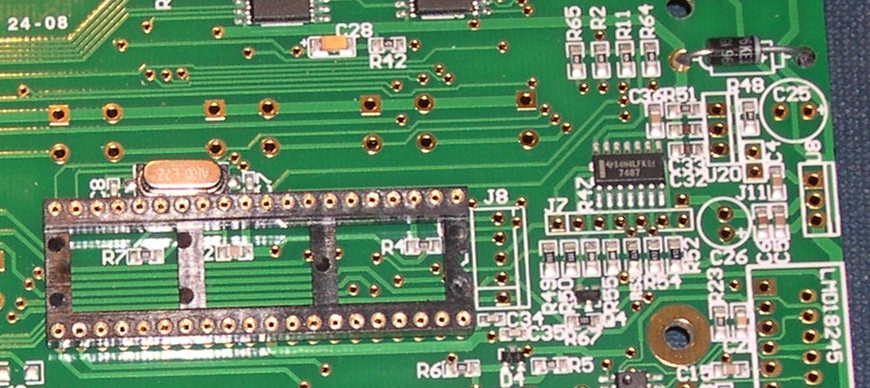

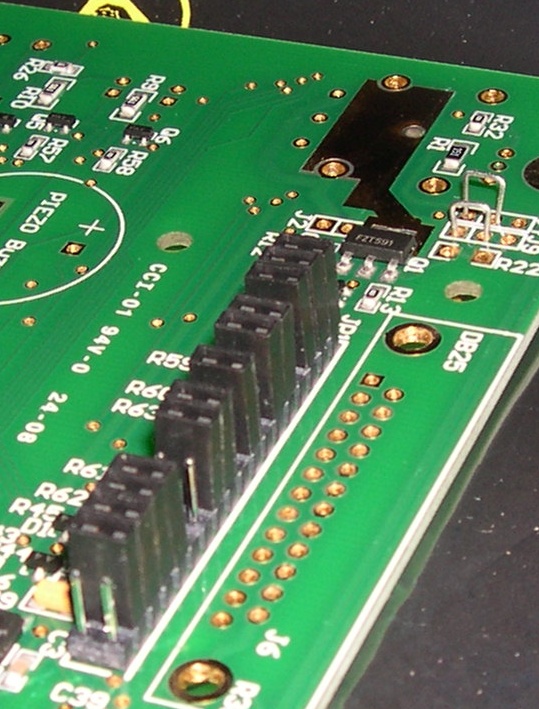

Next, after soldering the leads from the top side, install the 40 pin socket. Make sure the orientation is as below following the white silk screen legend shape.

Flip the board over and solder the two opposing pins.

Then flip the board back to the bottom side and make sure the socket is completely flush. You can heat one pin and press the socket closer to the board if not. You might even then have to do the other pin. After that solder the other 38 pins.

Next is the optional LCD Socket. The long pins of the LCD Header are inserted from the top side into the socket in order to align it and hold it in place. Then solder the surface mount pins of the socket. The short pins of the LCD Header will be soldered to the LCD display.

With the socket and optional header soldered in place it's time to make assembly a bit easier with the optional spacer kit since the rest of the parts stick out from the board..

Use the short screws for all but the top right hand spacer by the D5 bridge rectifier. That one gets a longer screw that will later be used to hold the LCD display.

Time to install R22, the LCD back light current set resistor.

Then the two filter capacitors making sure that the polarity is correct. + to plus, - to minus. A cap installed backwards will eventually explode.

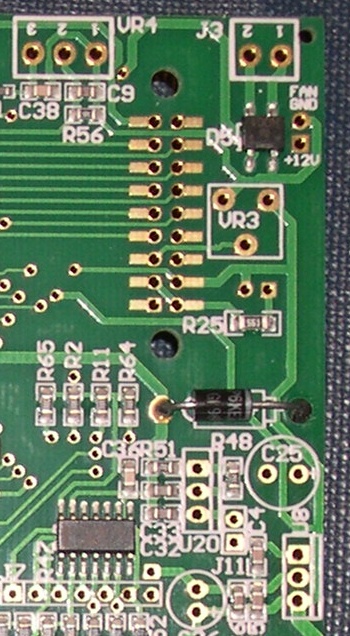

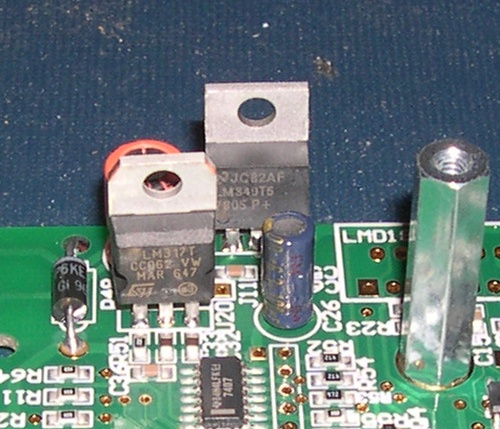

Also install R3, the LCD backlight contrast control. Turn the trim pot adjusting screw so it's all the way clockwise. Finally the regulators. The LM340-T5.0 goes closest to the edge of the board. The LM317 adjustable regulator is used to provide the 13.5V needed for programming the PIC for upgrades.

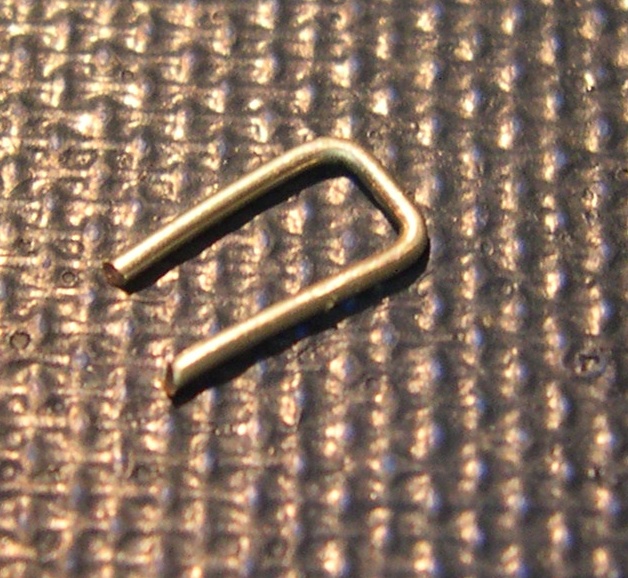

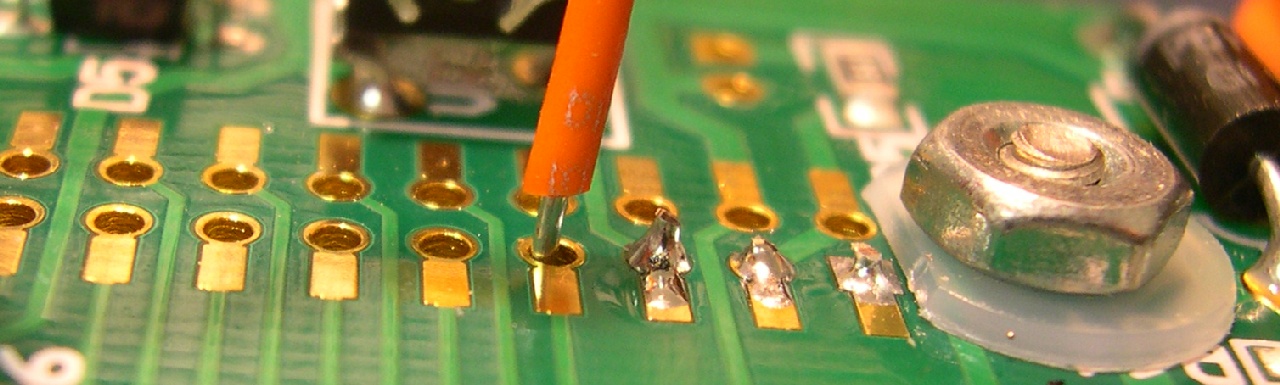

Now we start on the fiddly parts. The optional header/jumper kit makes this easier but for most applications the jumpers are done once and then left that way. Strip about 1/2" or 1cm of insulation from the solid 22g hookup wire. Cut it off and using your needle nose pliers form it into a U shape:

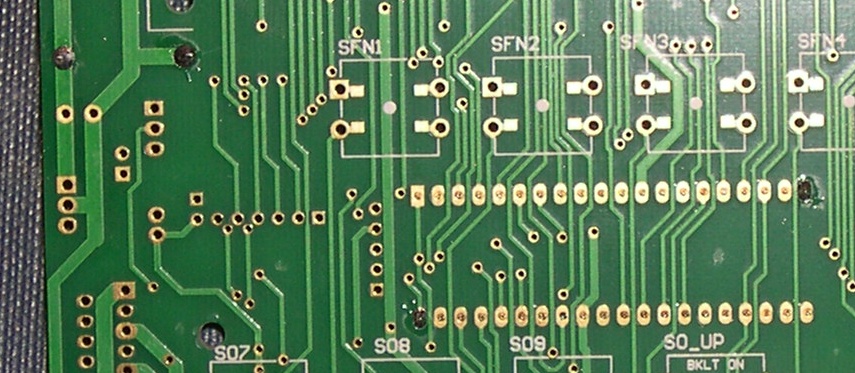

Bend it so that it just fits in the pair of holes but stands up from the surface of the board. This way you can cut it or remove it more easily in the future if needed. You will need fifteen jumpers.

]

]

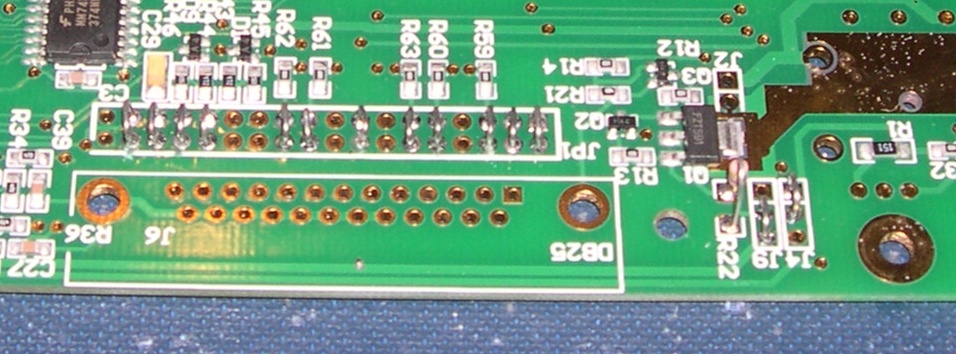

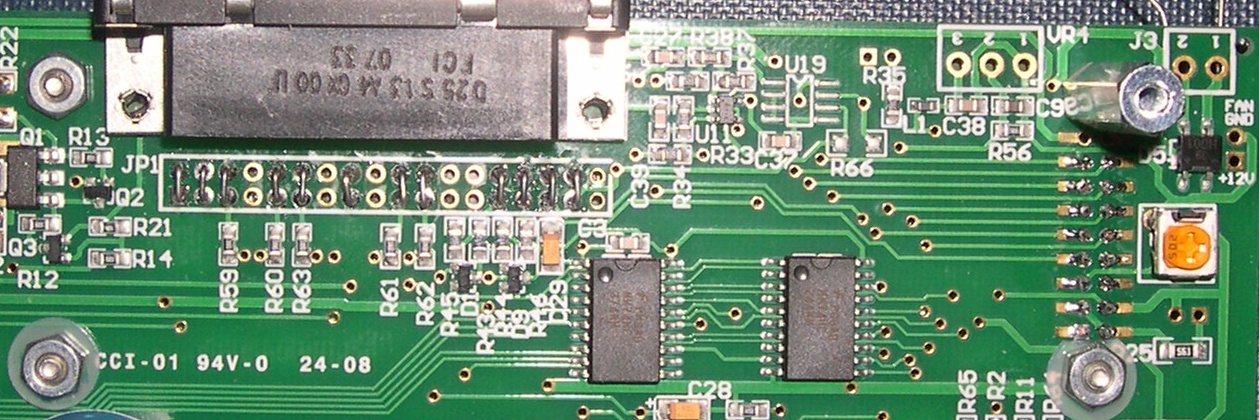

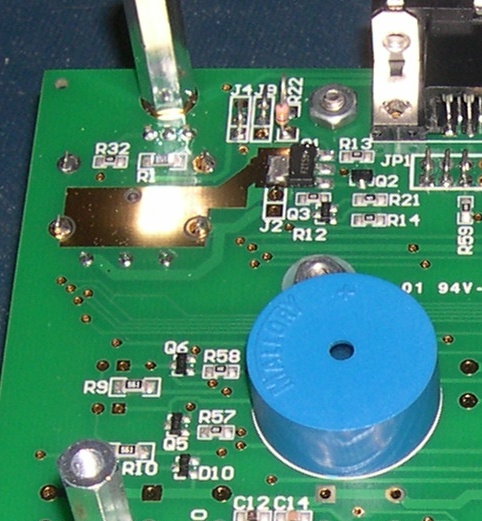

Note the J4 and J9 jumpers.

These two jumpers determine which voltages go to the DB-25 Pin #1 and to the LCD backlight constant current regulator. Most of us are probably using a simple opto interrupter or a Hall effect sensor that requires 5V. Jumper J4 connects 5V or 12V to Pin #1 of the DB-25. In most cases 5V is adequate. Similarly, the backlight for the display I'm supplying works best with 5V into the constant current regulator. A different LCD display needed a lot more current at a lower voltage so 5V was better for power dissipation. Jumper Block Pin 1 is the square pad and is 5V while Pin 3 is 12V.

NOTE The photo shows J9 in the 12V position but for best performance you should put it in the 5V position just like J4.

It's easy to solder them from the same side and then when they are all installed and soldered clip off the protruding ends from the top side so they won't touch the LCD display that will be mounted above them.

If you've purchased the optional jumper header you can install it as shown in the following photo. Note here J4 and J9 are in the 5V position. Solder the jumper header from the other side.

On the top side you must also install the programming voltage jumper.

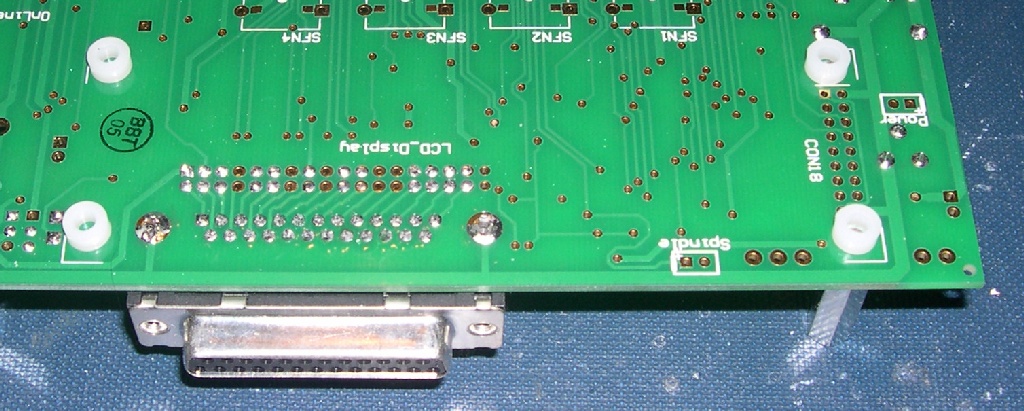

With the jumpers installed and soldered carefully insert the DB-25 connector on the bottom side of the board making sure all pins go through the holes. Ensure it makes good contact with the PCB and solder all 25 pins and the two mounting pins. Clip the DB-25 pins flush so they won't touch the LCD which is next to be installed. Notice in the photo below the bottom RH screw has been removed and the 4 optional 0.125" #4 spacers have been laid in place.

Place the LCD on top of the spacers and insert the 4 longer screws through the LCD, the spacers and the PCB. The Bottom RH screw can be immediately screwed into the spacer. Carefully turn the board on edge and use the nuts and washers to fasten the LCD into place. Trim teh one washer so it doesn't cover the LCD connector holes. In the photo below the LCD has already been soldered to the ELS PCB.

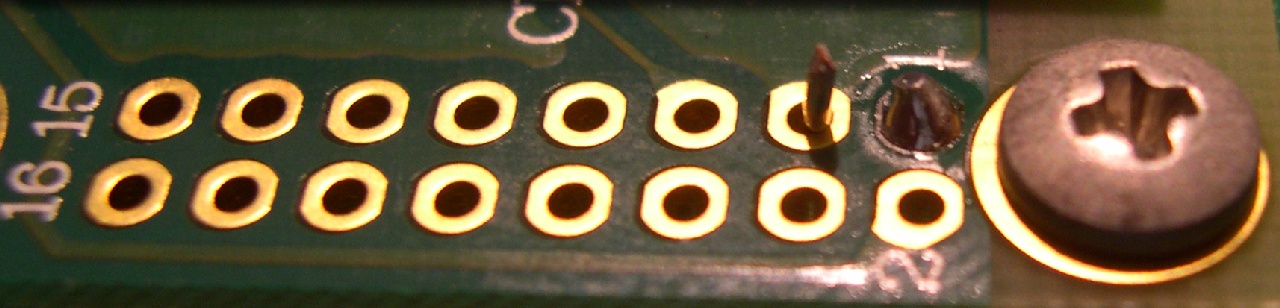

To connect the two there are several options. The low cost kit approach uses more of the 22g hook-up wire. Trim 1/2" or 12mm insulation from the end but don't clip it off yet. Then insert from the bottom side into LCD display so it comes out pin #1 and protrudes about .125" or about 1 or 2mm. Solder it.

Then turn the board over and clip the length of wire off leaving 1 to 2mm proud of the board

.

Solder this and then clip flush. Do this for all 16 connections after which you can install the beeper. Note the polarity of the pins. Get it wrong and it won't work.

.

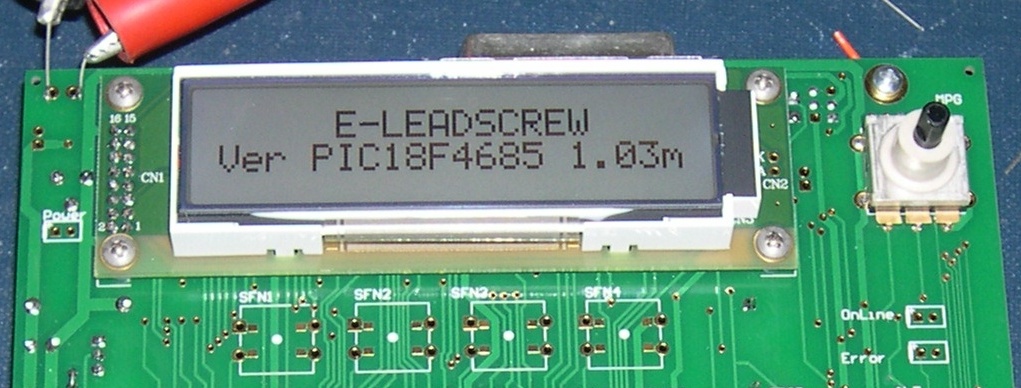

Finally insert the processor again taking note that PIN 1 is at the top right hand side. The notch in the processor is by J8..

Turn the board over so it's sitting on the spacers and install the MPG. The leads on this device are very fragile so it make take several tries to line them up and get the MPG installed. When it's done right it just slips into place. Solder the pins and mounting tabs.

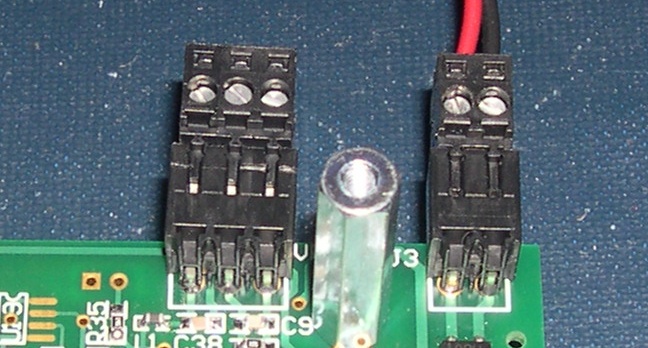

At this point, you can test it. Even without the buttons installed. But you do need power. There are all sorts of options on how to power the ELS so the basic kit doesn't come with connectors. If you use the optional PCB screw terminal kit you can install them now.

Or there's the optional CPC connector kit which provides power for both the ELS and the on board Micro-Stepper.

For a quick test you can just solder a couple of wires as shown below. Polarity of the power supply isn't important since the ELS has a bridge rectifier.

Left to install are the buttons and the LEDs. However, if you are adding the on board Micro-Stepper driver it's easier to install that first before the buttons so that you don't have to work around the buttons and button caps with a hot soldering iron.

Installing the Micro-Stepper Hardware

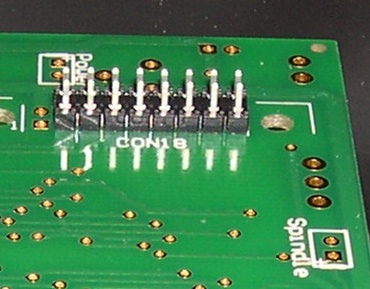

And now the switches. Snap each switch into the holes and solder from the bottom side. Mount the LEDs with spacers or insulate the leads. The short lead goes in the hole marked '+'.

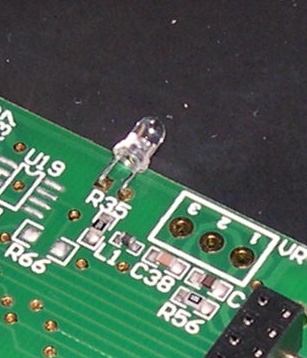

Here's a photo of how the Spindle LED is mounted.