Fabricating a custom heat sink for a 250W power supply.

Step 1: The board is done with Protel99 SE and then Altium. The step file imported and also fit with the AlibreCAM 3D modeling tool

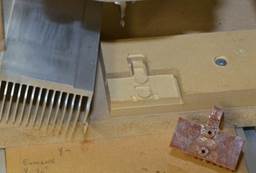

Step 1a: Model it with the 3D printer to make sure it fits, but there’s still that good feeling you get with actual hardware.

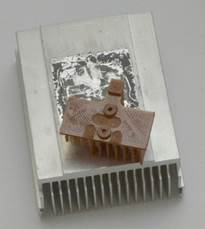

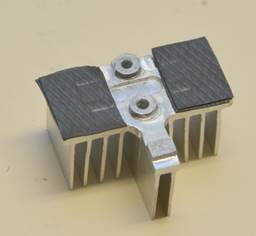

Step 2: Find an existing heatsink meant for a Pentium processor so that only the bottom of the heatsink needs to be machined

.

The slots in the bottom are to clear surface mount capacitors.

Step 3: Run the G-Code generated by AlibreCAM from the AlibreCAD drawing in MDF.

Step 4: Added the thermal conductive pads to create contact with the transistors. The two screw hole pads and the flat tab conduct to the ground plane and the power supply driver chip underneath.

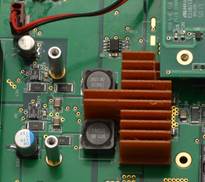

Step 5: Fits nicely.

Step 6: Have them made commercially including anodizing black.