Fluffing up the Sand when

a Muller canít be found!

(or

Click on the photoís if you want to see a larger image and then click BACK to get back to

this page.

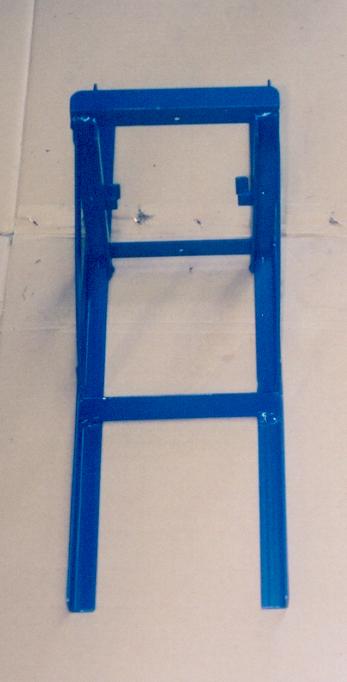

The Fluffer ready to go.

†††††††††††††

†††††††††††††

It starts with a frame

Which needs a motor and a disk with posts to break up the sand.

†††††

†††††

Cast out of aluminum and cleaned up by Jens on his lathe I marked out

and drilled the holes for the carriage bolts.†

The disk is well balanced and turns with almost no vibration.

††††

††††

The longer section of the propane cylinder has a cross piece and some

feet welded onto it and the cross piece rests on the two tangs on the

frame.† The feet sit on the angle iron

rails and although there are holes to bolt it in place I havenít found the

need.† The smaller part of the tank is

the funnel and I used a 2.125Ē hole saw on the drill press to cut the hole and

then tack welded the two pieces together.

Finally with it sitting on my plastic sand box I can fluff up the sand.

What I would do differently the next time is use the rails with the

point up or round tubing so that the sand wouldnít get caught on the

edges.† Itís not a real issue if the unit

stays in one place but annoying if I need to store it off the sand box.† Time will tell how well it works.† Iíve found that if I put a 2.125Ē x 3Ē cylindrical

screen in the inlet that the big clumps bounce around but donít always break

up.† The solution would be to put some

sort of impellor or spikes in the middle which would cause the chunks to

break.† Havenít tried that yet.